SEARCH

With the increasingly frequent use of insulation materials, rubber and plastic pipe also rise, the market is more and more extensive, today xiaobian with you to understand the rubber and plastic pipe manufacturers in the process of transportation need to pay attention to the problems.

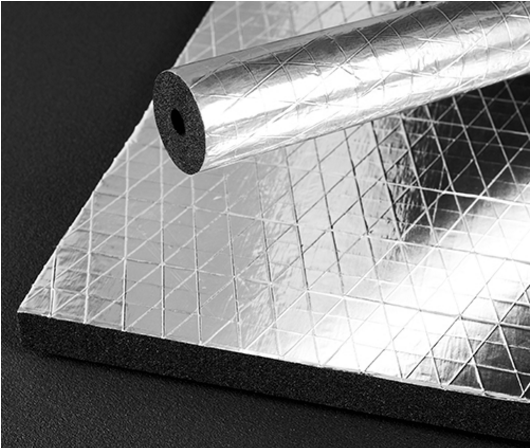

In our life, there are many places where rubber and plastic insulation pipe will be used, such as buildings, vehicles, central air conditioning refrigeration room, etc., the effect of heat preservation and cold protection is obvious, which is a qualitative leap in the heat preservation pipe industry. Many raw materials of products need to be transported before production, but we should pay attention to some things in the process of transportation, because raw materials in the process of transportation will inevitably cause the loss of raw materials, so we need to pay more attention to some things, rubber and plastic pipe manufacturers of raw materials in the process of transportation should pay attention to what problems?

First of all, we should pay attention to waterproof in the transportation process. Adding water to raw materials will increase the damage time. Such products may have other problems in the production process, so we should pay attention to this.

Secondly, pay attention to ventilation in the process of transportation. Some raw materials take a long time to transport, so we should reduce losses. At this point, we need ventilation to avoid overheating of raw materials and product loss, and achieve good results.

Finally, we should be careful not to damage the raw materials when loading or unloading. For fragile products, we should handle them with care.

Rubber hose manufacturers bring us quality products to help us survive the harsh winter and hot summer. But different quality products bring us the thermal insulation and cold effect is still different, so we must find a quality guarantee of the manufacturer, then the problem comes, where the rubber and plastic insulation pipe manufacturer is good?

UETERSEN New Materials Group Co., Ltd. is a comprehensive enterprise integrating research and development, production and sales of high-end thermal insulation materials and composite materials, which owns well-known brands such as UETERSEN and UK Yukon New Materials. As the benchmark of building insulation industry, Utson Group has the courage to break through and innovate, using its own advanced technology in material production and building science, producing glass wool, rock wool, rubber and other insulation acoustic fireproof materials.

Because its main raw material is rubber, so its toughness and winding excellent, can adapt to all kinds of construction environment. And there are a lot of excellent performance, such as convenient installation, beautiful appearance, to install in irregular parts can be arbitrarily cut. Low thermal conductivity, less water absorption on the surface of the rubber tube, effectively preventing steam from passing through the tube wall.

UETERSEN specializes in the production of glass wool, rock wool, rubber and other insulation acoustic fire materials, for domestic and foreign construction, industry, energy, transportation and other applications to provide safe and efficient thermal insulation, environmental noise reduction solutions.

Through this article, I believe that you have understood the problems that need to be paid attention to in the process of transportation of rubber and plastic pipelines. A little attention will not have any problems. If you have this requirement or question, you can contact us at any time, we have a professional answer for you.