SEARCH

Aluminum foil has a shiny silver appearance, so some owners and designers will prefer to add a layer of aluminum foil to rubber and plastic insulation materials. And that add a layer of aluminum foil, can improve steam insulation and moisture resistance, strengthen mechanical protection, improve the fire rating and outdoor anti-ultraviolet function. If that's what you're thinking, you're going to be disappointed!

Add a layer of aluminum foil, not only can not improve the fire rating and outdoor anti-ultraviolet performance, in addition to the cost of 25% to 40%, air conditioning system condensation risk will increase by 40 to 60%!

I thought: add a layer of aluminum foil can improve the performance of steam insulation and moisture resistance

In reality: rubber and plastic itself has excellent moisture resistance, but it is easy to dew with another layer

Perforated materials and fiber materials because of poor steam insulation and moisture resistance performance, easy to absorb water, so this kind of products generally need to add a layer of aluminum foil veneer as a steam insulation layer.

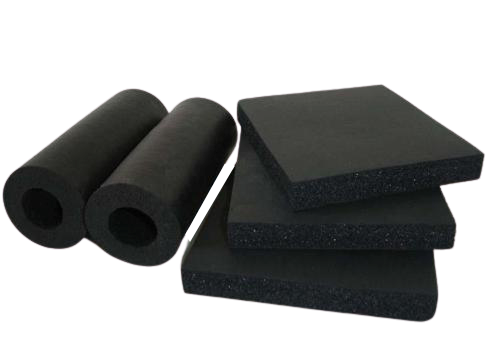

However, rubber and plastic insulation material is closed cell material, inside the independent bubble structure is enough to resist water vapor penetration, there is no need to add a layer of aluminum foil as a steam insulation layer.

External surface coefficient he (also known as surface heat release coefficient) is a comprehensive value of radiation and convection heat transfer coefficient, mainly affected by surface roughness, color, brightness, wind speed, temperature, etc. For the selection of anti-condensation thickness, the higher the surface coefficient he of insulation material is, the smaller the insulation thickness is needed, and the less the material consumption can be. Therefore, the heat preservation materials with high surface coefficient should be preferred for the air conditioning cold system.

Thought: add a layer of aluminum foil can strengthen mechanical protection

Reality: Most of the pipeline operation position is hidden, no mechanical protection needs

Rubber and plastic products are most used in construction pipes and equipment, and these pipes are basically run in the hidden position of the ceiling, ceiling and so on, in fact, there is no need for mechanical protection.

Thought: add one more layer of aluminum foil can improve the fire rating

In reality: building fire tests prove that adding a layer of aluminum foil rubber products fire performance does not increase but decrease

Many people mistakenly think aluminum foil is pure aluminum, but it's actually aluminum plastic film. Some aluminum foil with very few wrinkles even contains no aluminum. Aluminum foil is mostly polyester/plastic "aluminum composite" layer, fire performance is not good. Therefore, in the building fire test method, aluminum foil will not improve the fire level. If you use cheap aluminum foil, you can actually lower the fire rating.

In mind: change the appearance of color, good-looking

In reality: the surface of aluminum foil is easy to fold and not beautiful

Aluminum is far less elastic than rubber and plastic, so when the pipeline temperature changes, rubber and plastic insulation itself can achieve uniform shrinkage; Aluminum foil, on the other hand, tends to become crumpled because it has little elasticity. In order to meet the situation of improved wrinkles, some manufacturers will even use aluminum film instead of aluminum foil. Although the folds have improved, the material is no longer "aluminum" foil as customers understand it.

Think: outdoor use can resist ultraviolet light

Reality: Aluminum foil is not strong enough for outdoor protection

Uv resistance should be determined based on testing. The thickness of aluminum foil containing metal aluminum is less than 7 microns, which can be imagined in the outdoor anti-ultraviolet effect.

In a word, the selection of rubber and plastic insulation materials for the HVAC system should be based on the dimensions of environmental protection, energy saving, moisture resistance and safety. Emphasizing the surface layer too much and ignoring the essence and quality of insulation layer is undoubtedly putting the cart before the horse. There's no need to add another layer