SEARCH

In Shenzhen Pingshan Biomedical Base, the prototype of a Greater Bay Area steel frame tube biological industrial Park is emerging, which is the Pingshan Biomedical Industry Accelerator Park project. As a project undertaken by China Construction Technology Company in the integrated mode of "R&D + design + manufacturing + procurement + construction", this project creatively adopts the new structural system of "local concrete core tube + concrete-filled steel tube column + steel beam + steel truss floor bearing plate + laminated floor plate +PC exterior wall". It is committed to building a comprehensive demonstration area of biological industry in the core area of biomedical industry and a modern "biotechnology new city" with carbon-neutral technology demonstration "integration of industry and city". The main construction functions of the building are bio-pharmaceutical, medical equipment and pollution-free workshop, animal laboratory and commercial supporting facilities.

The project is located at the junction of Jinsha Community and Sha Tin Community in Pingshan District, Shenzhen, next to the Sha Tin Station of Metro Line 14 (planned). The project covers a total area of about 106,000 square meters, with a total construction area of about 689,000 square meters, including 12 factory buildings and 3 super high-rise buildings, supporting dormitories, canteens, commercial areas, research and development rooms, factories and other facilities.

According to reports, after the completion of the project will provide Shenzhen intelligent computer room, biochemical sewage combined treatment station, become an important booster for the development of biological industry in Pingshan District and even Shenzhen, in the scientific and technological research and development, industrial agglomeration, industry-city integration development and other aspects of the demonstration role, will further gather biological industry resources, accelerate the development of Pingshan District in the future industry.

When accelerating the promotion of industrial resources, it also promotes the green and energy-saving development of industrial parks. For a highly professional accelerator park, modern energy saving design is an important link at present, such as building facade energy saving and heat preservation, heat pipeline energy saving, etc. Similarly, in HVAC design, pipe insulation is also a major focus.

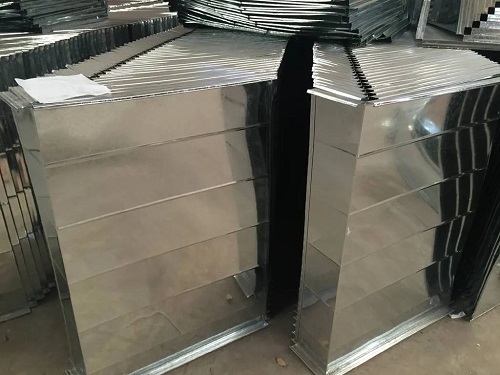

In Pingshan Pharmaceutical Accelerator Project, Uetersen South China Company is responsible for the supply of HVAC thermal insulation packaging materials. Glass wool products, as insulation wrapping materials for central air conditioning duct systems, are currently a more economical, convenient construction and stable performance solution in the insulation industry.

In the medical acceleration project, the environmental requirements are dust-free and clean. Uetersen glass wool has less dust and strong compression resistance compared with special space such as laboratories for medicine. During the installation process, special aluminum foil tape is used to seal and fix the pipe to reduce the temperature loss and avoid dust and water vapor generation.

"Shenzhen" means field ditch in the Hakka dialect, and "Shenzhen" appeared as a place name in the eighth year of Yongle in the Ming Dynasty. Located in the coastal, climate change, often high temperature and rainy, belongs to the subtropical Marine climate. The humidity brought by the climate is completely different from that in the north. As the insulation material used in the south, attention should be paid to avoid water vapor penetration. The thermal insulation performance of glass wool needs to be completed by the small holes formed by the interlacing of fibers. Once the cold bridge effect occurs, the thermal insulation effect will be greatly reduced.

Uetersen glass wool has high hydrophobicity, which can greatly reduce the possibility of reducing thermal insulation performance and service life caused by water vapor infiltration into the glass wool. Meanwhile, Uetersen glass wool produced by fiber forming equipment and technology has less slag ball content, thin fiber diameter and uniform distribution. Under the same conditions, the smaller the diameter of the fiber, the smaller the thermal conductivity of the product, the better the thermal insulation performance of the product.

Uetersen adhere to the research and development of new thermal insulation material technology, in the glass fiber technology, has been in the forefront of the industry. The products are used in aviation, high-speed rail, roof curtain wall, high temperature thermal industry and other fields. Practice pragmatic brand values, committed to the sustainable development of building energy conservation and insulation.