SEARCH

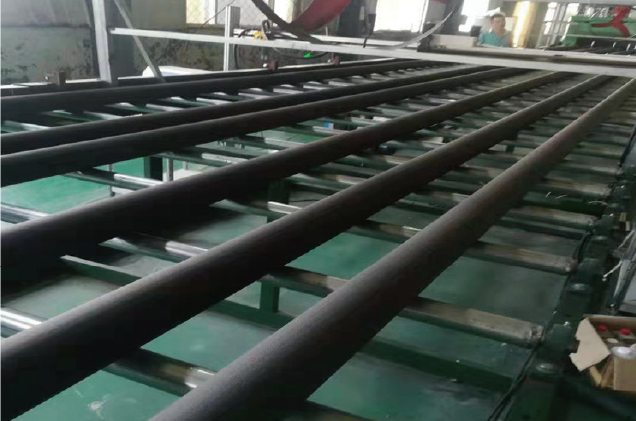

With the vigorous development of thermal insulation materials, rubber and plastic thermal insulation products are also welcomed by everyone. Among them, rubber and plastic insulation board is very popular. Rubber and plastic insulation board is a form of rubber and plastic insulation products. Rubber and plastic insulation board products are widely used in various industries because of their advantages.

Uetersen rubber and plastic performance characteristics:

1, low thermal conductivity: Uetersen rubber plastic thermal conductivity in the average temperature of 0℃, can be as low as 0.034W/M.K, in the same external conditions, the use of relatively thin thickness of the product, can achieve the same thermal insulation effect of traditional insulation materials.

2, flame retardant performance is good: rubber and plastic contains a large number of flame retardant smoke reduction raw materials, the smoke concentration generated when burning is very low, and in case of fire does not melt, will not drop the fire ball, the material combustion performance is far better than the C class international standards, to ensure safety and reliability.

3, good flexibility: rubber and plastic materials have good flexibility and toughness, easy to deal with bending and irregular pipeline construction, and can save labor and materials; Superior to high elasticity, thus minimizing vibration and resonance in the use of chilled water and hot water pipes.

4, high moisture resistance factor: rubber and plastic materials have high moisture resistance factor (μ≥10000), so as to ensure that the material has excellent moisture permeability resistance, stable thermal conductivity in the process of use, prolong the service life of the material, reduce the operating cost of the system.

5, environmental health: Uetersen rubber do not contain chlorofluorocarbons (CFC) and other harmful substances, do not contain formaldehyde, do not contain heavy metal and silicon, no fiber dust, ammonia and sulphur content of particulate matter, volatile gas and organic matter to release a quantity, greatly satisfy the semiconductor clean room, clean room, and other areas of the application of ultra high requirements, but also with the eu ROHS, REACH certification.

Storage mode of rubber and plastic insulation board:

I believe we all know that rubber and plastic board is to be stored in winter, so how should rubber and plastic board be stored in winter?

Winter cold, heat preservation is the key work, rubber and plastic board because of its excellent insulation in the autumn and winter season demand growth is relatively large. As a rubber and plastic insulation material manufacturer, it is very important to do a good job in the storage of plate pipe products in the wet autumn and winter. It is rainy and snowy in winter, and the air after snow is humid, so manufacturers should pay more attention to the ventilation of the warehouse after snow, disperse the humid air in the warehouse, prevent the use of insulation board from being affected by damp, and store rubber and plastic insulation board in winter, the selection of the warehouse is very important. We suggest to choose the warehouse with a sunny side and ensure that the warehouse is dry and clean. There should be no excessive water source and no open fire and corrosive substances in the warehouse, otherwise the storage of thermal insulation board and thermal insulation pipe will be affected.

There are a lot of friends for rubber and plastic plate storage experience, we do not worry too much, if not experienced friends according to the above xiaobian to share the knowledge to do storage is also ok.